The paper pulp forming machine is the equipment that transfers waste paper into various types of practical paper trays and paper packaging, such as egg trays, egg cartons, fruit trays, seedling trays, cup trays, shoe trees, bottle packs, food plates, etc. These end products are all made from recycled paper, such as waste magazines, newspapers, cardboard boxes, etc., and can be recycled again after they fulfill their mission. With excellent abrasion resistance and hardness, pleasing appearance, as well as an efficient and environmentally friendly production process, they are gradually replacing traditional plastic packaging products and playing an increasingly important role in the packaging industry.

Pulping System

(1) Put the raw material into the pulper, add an appropriate amount of water for a long time, stir the waste paper into pulp, and store it in the storage tank.

(2) Put the pulp in the pulp tank into the pulping tank, adjust the pulp concentration in the pulping tank, and further stir the white water from the return pool and the thick pulp from the storage tank through the homogenizer. After adjusting to the applicable pulp, put it into the feed pool for use in the molding system.

Equipment used: pulper, homogenizer, slurry pump, vibrating screen, pulp disintegrator.

Paper Pulp Forming System

Pulp Forming Machine

Pulp Forming Machine Pulp Forming Machine

Pulp Forming Machine Pulp Forming Machine

Pulp Forming Machine

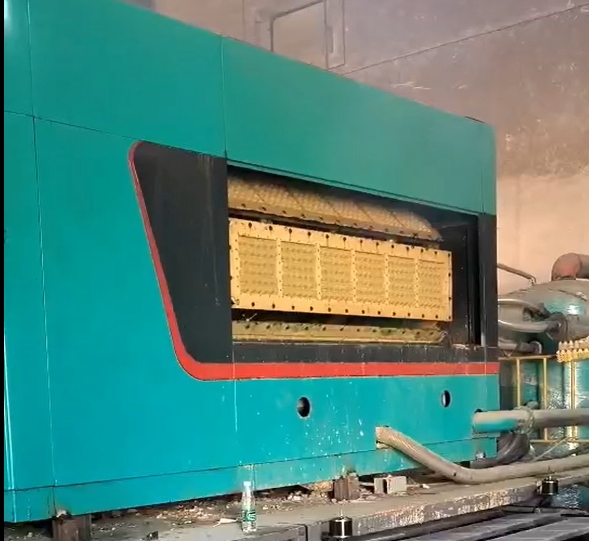

Paper pulp forming is a crucial stage in the entire paper product manufacturing process, directly influencing product quality. In the pulp molding machine, uniform pulp adheres to the mold, undergoes shaping under certain pressure, and then exits the mold in a semi-dry state to proceed to the next production step. The entire process is fully automated and requires no manual intervention.

Paper Tray Drying System

(1) Natural drying method: the product is directly dried by weather and natural wind.

(2) Traditional drying: brick tunnel kiln, heat source can choose natural gas, diesel, coal, drying wood and other heat sources

liquefied petroleum gas.

(3) New multi-layer drying line: 6-layer metal drying line can save more than 30% energy compared with transmission drying. The main heat source is clean energy such as natural gas, diesel, liquefied petroleum gas and methanol.

Finished Product Auxiliary Packaging

1) Automatic stacker.

(2) Packing machine.

(3) Transfer conveyor.

What Products Can Pulp Forming Machines Produce?

Egg tray

Egg tray Packaging Box

Packaging Box Paper Egg Box

Paper Egg Box Paper Egg Box

Paper Egg Box Paper Egg Box

Paper Egg Box Paper Mask

Paper Mask Paper Shoe tray

Paper Shoe tray Paper Tray

Paper Tray Paper Tray

Paper Tray Paper Tray

Paper Tray

Pulp molding machines are mainly used to produce pulp molded products and packaging products, such as paper egg trays, pulp molded egg boxes, paper shoe stretchers, automobile wheel packaging, fruit trays, seedling trays, cup trays, bottle packs ect.