Egg Tray Making Machine for Sale

Egg Tray Machine (Pulp Moulding Machine) For Sale

Brand: Shuliy.

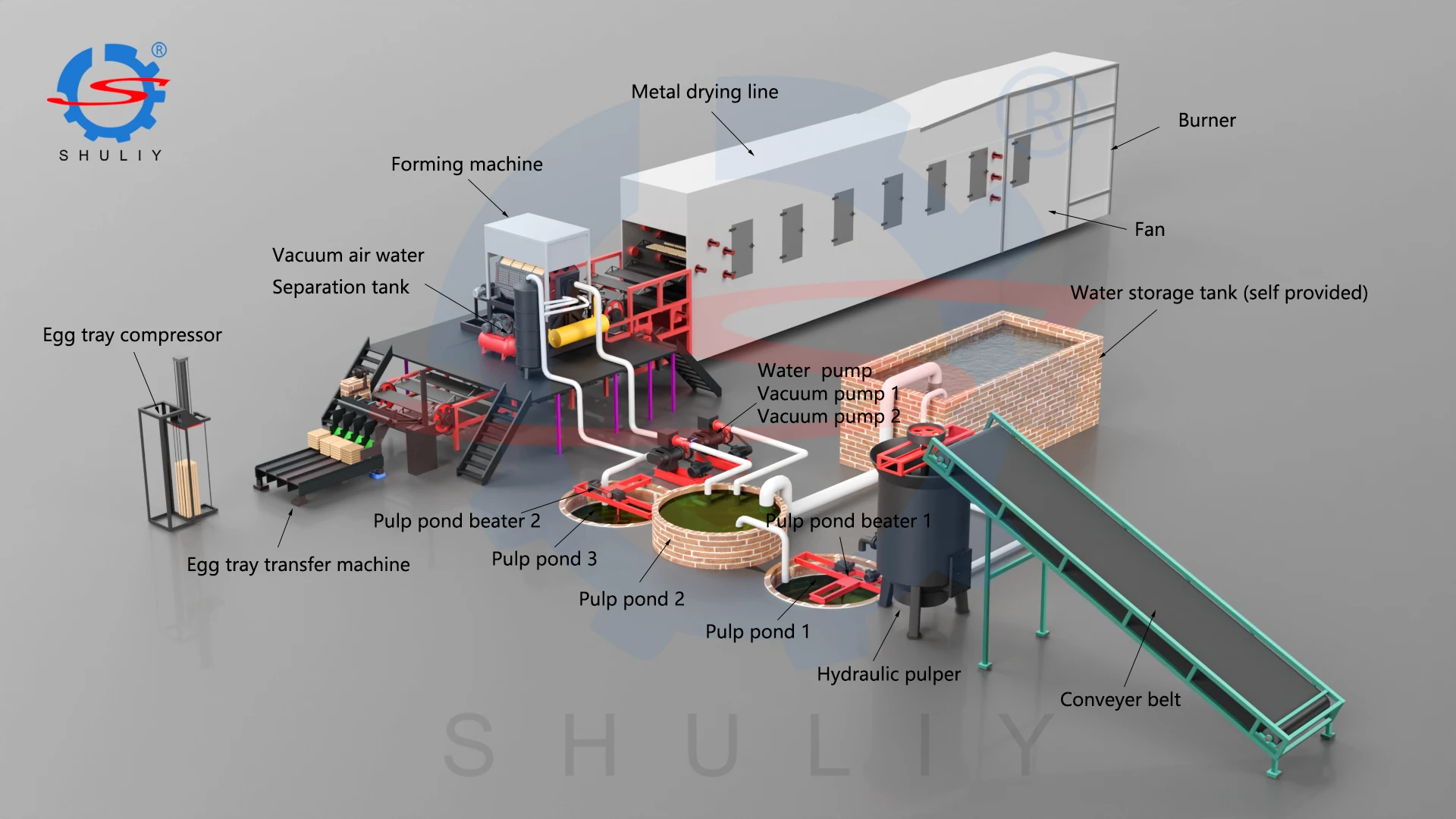

Function: automatically produce egg boxes, fruit trays, coffee cup trays, seedling trays, shoe trays and other pulp trays.

Output capacity: 1000pieces to 7000pieces per hour (customized capacity available).

Common Raw Materials: waste paper, cardboard boxes, newspapers.

Drying System: natural, brick, drying room drying, metal drying.

Parameters of Egg Tray Making Machine

We can provide customized solutions according to your requirements. If you need an egg tray production line with a larger output, you can contact us.

| Model | SL-1500 - 3*1 | SL-2500 - 3*4 | SL-3000 - 4*4 | SL-4000 - 4*8 | SL-5000 - 5*8 | SL-7000-6*8 |

|---|---|---|---|---|---|---|

| Capacity/h | 1500p | 2500p | 3000p | 4000p | 5000p | 7000p |

| Power/h | 38kw | 55kw | 60kw | 95kw | 95kw | 120kw |

| power supply | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ |

| weight | 3000kg | 4000kg | 4800kg | 7000kg | 8000kg | 10000kg |

| Dimensions (host) | 2800*2200*1900 | 2900*1800*1800 | 3250*1800*1800 | 3250*2300*2500 | 37000*2300*2500 | 3200*2300*2500 |

| Paper consumption/h | 120kg | 200kg | 240kg | 320kg | 400kg | 480kg |

| Water consumption/h | 240kg | 400kg | 480kg | 640kg | 800kg | 960kg |

| dryer | airing/drying box | airing / drying room | brick/metal drying | brick/metal drying | brick/metal drying | brick/metal drying |

The egg tray machine is also a type of pulp forming machine. It is mainly used to produce egg trays. By changing the mold, it can also be used to produce egg boxes, fruit trays, coffee cup trays, seedling trays, shoe trays and other pulp trays.

The egg tray machine can process waste paper, cardboard and other recyclable paper materials into pulp, mold it, and dry it into paper trays of different sizes and shapes.

Model:

SL-1500 – 3*1, SL-2500 – 3*4, SL-3000 – 4*4, SL-4000 – 4*8, SL-5000 – 5*8, SL-7000 – 6*8, Larger output can be customized.

Shuliyglobal’s egg tray machines are cost-effective, long-lasting and come in a full range of models. Customized egg tray production solutions can also be designed according to customer specific needs.

Model:SL 6*8

Capacity:7000p/h

Dryer: brick/metal drying

Model:SL 5*8

Capacity:5000p/h

Dryer: brick/metal drying

Egg Tray Raw Materials

The raw materials used by our egg tray machine are usually waste paper and water. Generally, the ratio of water to paper is 3:1. There are many materials that can be used to make egg trays, such as cardboard boxes, books, magazines, A4 paper, waste paper trays, paper products, cardboard, newspapers, office paper, etc.

The type of raw material may affect the quality of the final paper pallet product. For example, using waste paper with a high ink content may result in a poor-looking egg tray, while using low-quality paper may result in an egg tray that is brittle and easily deformed. Therefore, to produce high quality egg trays please contact us for details.

Molded Paper Trays

The final products produced by our egg tray machines are a variety of pulp molded products including egg trays, egg boxes, fruit trays, cup holders, shoe racks and many other packaging solutions. These paper trays provide excellent protection and cushioning for the products they hold. They are lightweight, sturdy and easy to handle and transport. In addition, they are biodegradable and we can provide customers with special mold customization.

Metal drying (suitable for egg tray production lines with high output and high degree of automation);

Drying room drying;

Brick kiln drying;

Natural drying (suitable for egg tray production lines with low output and large space).

Egg Related Machines