Introduce of Paper Pulper Automatic Metal Dryer

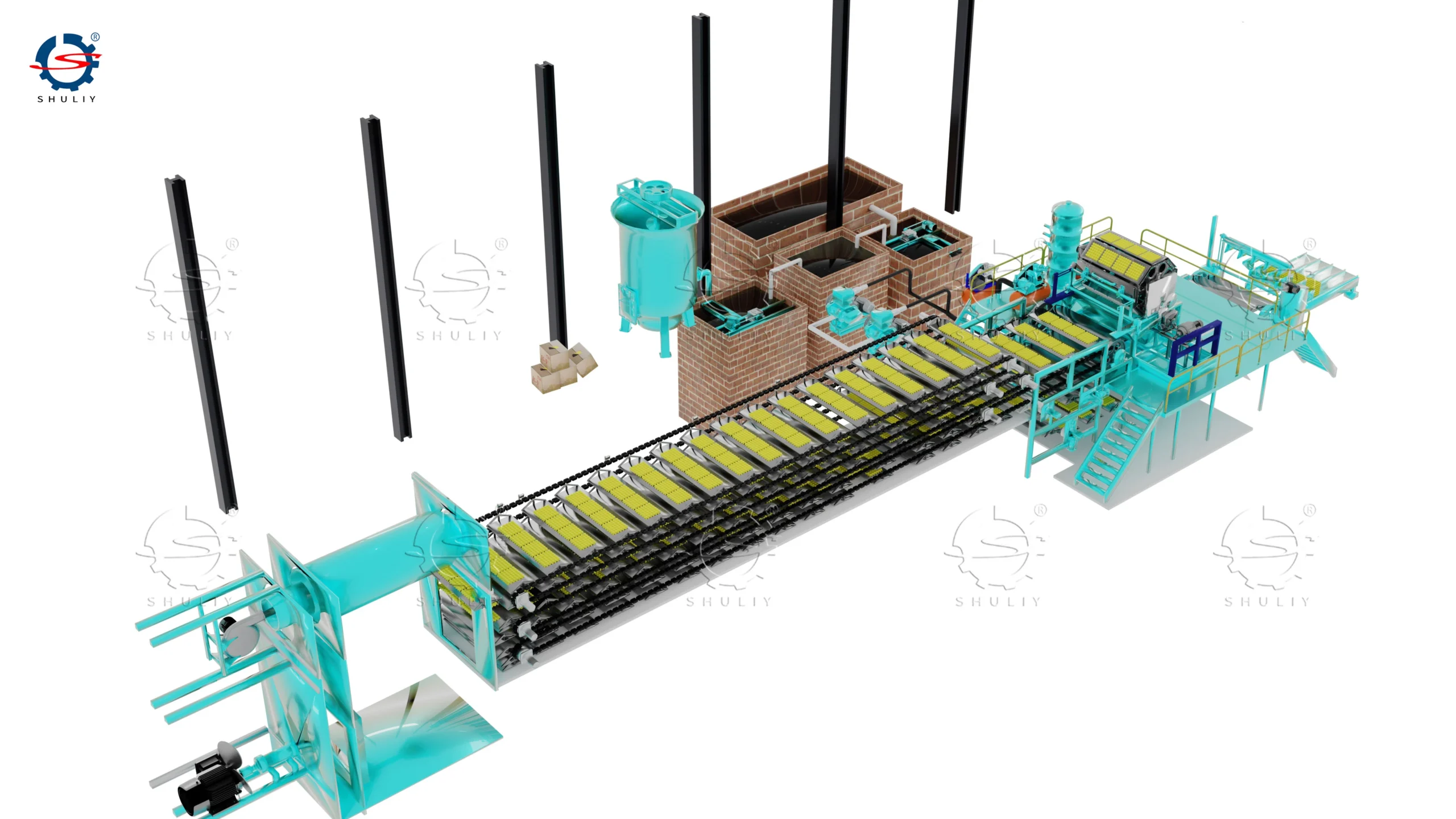

The formed egg tray enters the drying room through the tray. After 6 layers of drying for 25 minutes (180-200 degrees), it comes out from the lower end. The length of the drying room is 18 meters * 6 layers. The fuel options are generally coal, wood, and natural gas. , diesel, etc.

Advantages: small footprint, effective energy saving, high degree of automation.

Introduce Of Drying Room

Place the formed egg tray on the tray (galvanized) and then put it on the drying rack, push it into the drying box, and bake it for half an hour to complete the drying process. 10-12 trolleys can be placed in the box, and each trolley can hold 90-100 egg trays. An additional 10 trolleys are provided for easy recycling.

Advantages: Production can continue as usual in windy or rainy weather, and it occupies a small area

Disadvantages: Greater investment in manpower is required

Introduce Of Traditional Brick Kiln Drying Egg Trays

The formed egg tray enters the drying tunnel through the mesh belt, and is dried for 15 minutes (180-200 degrees) and then comes out from the other side. The drying length is generally 40-70 meters. The fuel selection is generally coal, wood, Natural gas, diesel, etc.

Advantages: The construction cost of multi-layer drying is lower than that of multi-layer drying, and it can also be automated.

Disadvantages: long floor space and high drying costs