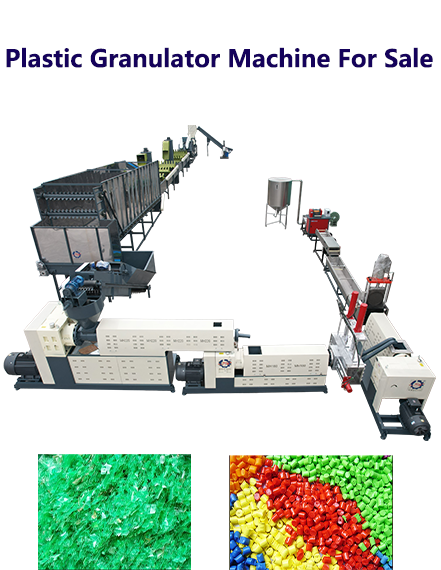

Plastic Granulator Machine

Plastic recycling line

Brand: Shuliy

Function:Processing waste plastics into clean plastic flakes or recycled plastic pellets

Capacity: 100kg/h, 200kg/h, 300kg/h, 500-800kg/h,1-5t/h.

Particle Length: 4mm(conventional), can be customized.

Particle Diameter: 3mm(conventional), can be customized.

Warranty: 1 year.

Advantage:Chinese factory, 14year R&D experience, high cost performance, fast delivery.

Service: Free customized slution. Installation and debugging. Free training operation. Welcome to visit our factory.

Plastic Recycling Machine Applicable Materials

t is suitable for the production of PET, PP, PE, PS, ABS, PA, PVC, PC, POM, EVA, LCP, PMMA and other plastic recycling granulation.

The Final Product Of The Plastic Recycling Line.

Process waste plastics into clean plastic flakes or recycled plastic pellets according to project requirements

Introduction Of Plastic Granulator Machine

Shuliy plastic granulator machine mainly used for processing waste plastic films (industrial packaging films, agricultural plastic films, greenhouse films, handbags, etc.), woven bags, agricultural convenience bags, pots, barrels, beverage bottles(cold drink bottle such as mineral water bottle, soda water bottle, coke bottle ect.), furniture, daily necessities, etc., suitable for most common waste Plastic, which is a plastic recycling processing machine that is widely used in the waste plastic recycling industry and is more popular for users.

With special double-stage screw design and different configurations, it is suitable for the production of PET, PP, PE, PS, ABS, PA, PVC, PC, POM, EVA, LCP, PMMA and other plastic recycling granulation. The reduction box adopts the design of high torque, which realizes the performance of noiseless and smooth operation. The screw and barrel are specially hardened, which has the characteristics of wear resistance, good mixing performance and high output. The design of vacuum exhaust or ordinary exhaust port can discharge moisture and waste gas during the production process, so that the material can be discharged. It is more stable and the colloidal particles are stronger, which ensures the good quality of the product.

Principle: The process of high temperature melting, plasticization and extrusion is used to change the physical properties of plastics to achieve plasticization and molding of plastics.

The main equipment of this production line is suitable for recycled various plastics materials such as PET/PP/PE/EPS/HDPE and so on,with an hourly output of 100kg/h, 200kg/h, 300kg/h, 500-800kg/h, 1-5t/h and other different outputs,which is an automatic assembly line from washing and crushing to granulation.

Recycle different plastics, the machine configurations of plastic recycling lines are different.

Leave a message to tell us what kind of plastic you want to recycle, and we will provide you with exclusive plastic recycling machine solutions!

Shuliy Machinery

4

2,000

120+

3500+

13Y

Successful Case

3000+ successful cases, exclusive plans can be customized, leave a message for more details.

our services

One-stop service

Shuliy machine provide you with perfect solutions with first-class service, allowing you to enjoy a pleasant purchasing process.

Pre-sales advice

Any inquiry will be replied within 24 hours.

Professional sales manager

The sales manager gives suggestions or quotations based on the customer’s specific needs.

Technical Support

Special projects require engineers to develop and customize machines to provide the perfect solution.

Welcome to visit the factory

Provide you with a professional factory tour guide. Pick up at the airport free of charge.

After-sales

Delivery, installation, training.

Successfully shipped to customer factory

Machine is being shipped

Plastic recycling line being installed