Starting an egg tray manufacturing plant is a big decision. If you are interested in this industry and want to know more information, you can leave a message to contact us.

This article covers everything you need to know to install and run an egg tray manufacturing plant. From the initial planning stages to equipment selection, we’ll guide you through every step of the process.

Guide to Starting an Egg Tray Manufacturing Factory

Step One: Research and Planning

Starting an egg tray manufacturing factory requires research and planning to ensure the success of the egg tray factory business. This process includes identifying your target market, competing, and developing a solid business plan.

First, you need to research the demand for egg trays in your target market. You can do this by communicating with potential customers such as egg farms, grocery stores, and restaurants. You can also conduct egg tray demand market research by reviewing egg tray production industry reports and analyzing market trends.

It is important to identify your target market for selling egg trays and understand the needs and preferences of that market. Are they looking for pallets made from recycled materials? What size egg trays do they need? Understanding your customer base will help you tailor your products to meet their needs.

Once you have a clear understanding of your target market, it’s time to research your competitors. Who else in your target market sells egg trays? What are the pros and cons of their egg trays? What’s unique about your egg trays? Answering these questions will help you build a competitive advantage and stand out in a crowded market.

Once you have this information, you can start developing your business plan. Your plan should include your mission statement, business goals, financial projections, and marketing strategy. It’s important to set realistic business goals and develop a plan to achieve them.

Your business plan will serve as a roadmap for your egg tray manufacturing plant and help you stay on track. It is important to review and update your plan regularly to ensure you achieve your goals and adapt to market changes.

In addition to your business plan, you may also need to prepare funds for your egg tray manufacturing plant. This can include existing funds, loans, grants or investments. You’ll need to provide potential investors or lenders with detailed plans and financial projections to demonstrate the viability of your business.

Starting an egg tray manufacturing plant is a daunting task, but with thorough research and planning, you can build a successful business in this growing industry.

Step Two: Equipment Selection

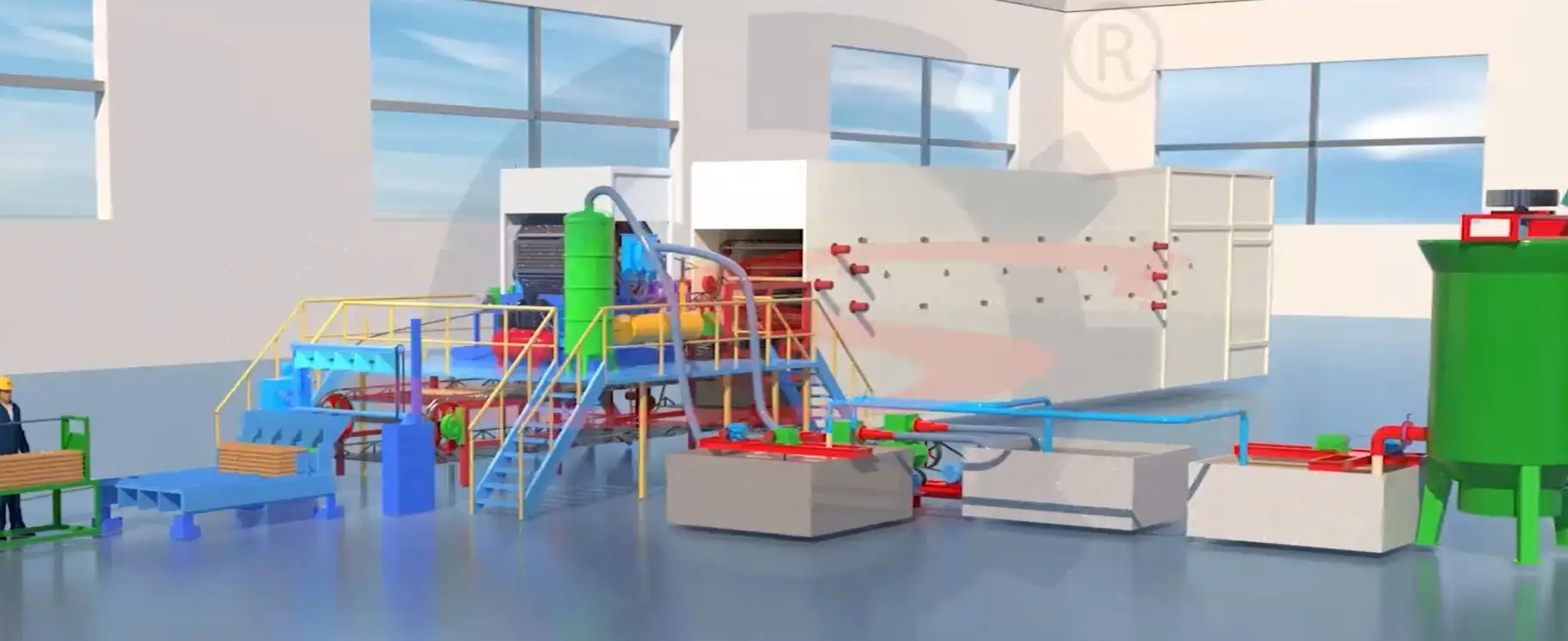

Once you have a solid business plan in place, it’s time to choose the equipment you’ll need to start an egg tray manufacturing plant. The key equipment you need includes pulp systems, pulp molding machines, drying systems and packaging systems.

Pulp system:

The pulp machine can convert all kinds of waste paper into pulp.

Pulp-Making-Machine

Pulp-Making-Machine

Pulp molding machine:

Pulp molding machine is the core of egg tray manufacturing plant. It is responsible for converting pulp into egg trays. There are many different types of pulp molding machines available, including manual, semi-automatic, and fully automatic machines. ShuliyMachine sells various shapes and specifications of egg tray forming molds. Each size of machine has its own advantages and disadvantages. Egg tray machines with large production capacity will also be more expensive, so choose the machine with the capacity that best suits your business needs and budget. Very important.

Egg-Tray-Machine

Egg-Tray-Machine

Egg tray drying system:

After the egg tray is formed, it must be dried before it can be packaged and shipped. Drying methods are divided into natural drying, brick kiln drying, drying room drying, metal drying. The drying system usually consists of a dryer and a conveyor system. Dryers can be powered by electricity or natural gas, and it is important to choose a system that is energy-efficient and cost-effective.

metal-drying

metal-drying

Egg tray packaging system:

Once the egg tray is dry, it must be packaged and prepared for shipping. Packaging systems typically include palletizers and shrink wrappers. A stacker stacks the egg pallets while a shrink wrapper wraps them in plastic for protection during shipping.

When selecting equipment for your egg tray manufacturing plant, it is important to consider your production capabilities and the quality of your final product. You need to choose equipment that is reliable, efficient and capable of producing high-quality egg trays.

It’s also important to consider the cost of the equipment and the availability of replacement parts and maintenance services. You want to choose equipment that is within your budget and is easy to repair if it breaks down.

Finally, it’s important to work with a reputable supplier who can provide ongoing support and guidance as you start and grow your egg tray manufacturing plant. By choosing the right equipment and suppliers, you will build a successful business in the egg tray manufacturing industry.

Step Three: Location and Settings

Once you have selected your equipment, it’s time to prepare the appropriate location for your egg tray manufacturing plant. You need a space large enough to accommodate your equipment and easy to load.