Ligne de lavage et de granulation PET 1T

Fournir des solutions personnalisées

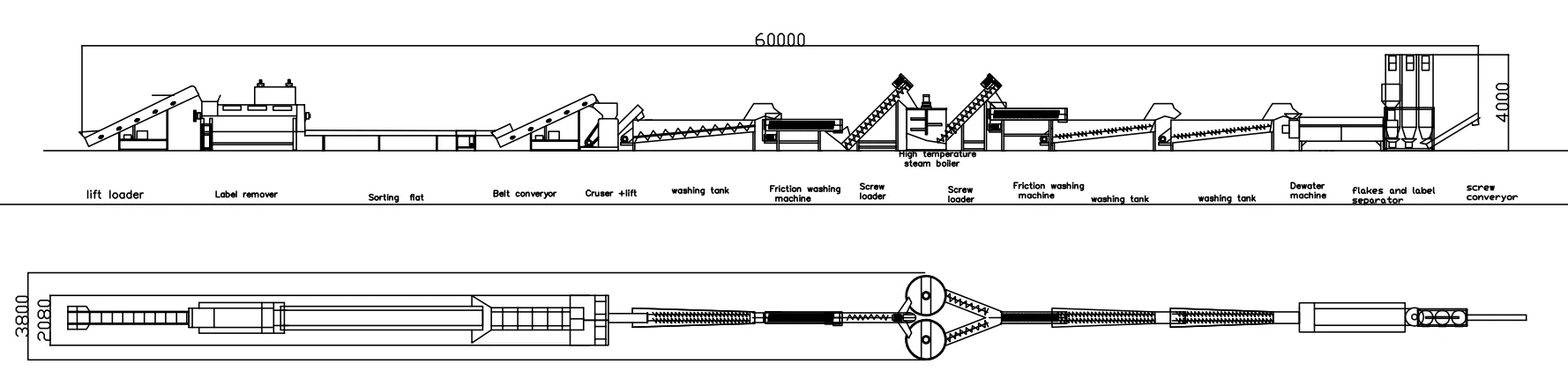

Ligne de lavage et granulation de bouteilles PET Shuliy

Nos lignes de granulation et de lavage de bouteilles PET standard sont des solutions complètes pour convertir les bouteilles PET sales en flocons de PET propres pour la transformation en granulés de plastique ou la production d'une variété de produits finis en plastique.

Nous proposons des capacités de granulation de lavage standard allant de 500 kg/heure à 5 tonnes/heure, et pouvons également personnaliser des lignes de lavage de recyclage PET de plus grande capacité.

La ligne de production de recyclage du PET de Shuliy est entièrement automatique et chaque machine de recyclage est reliée par un convoyeur à bande ou à vis. De plus, l’ensemble de la ligne de nettoyage peut être contrôlé à partir d’un panneau de commande électrique central et d’une armoire.

Si votre matière première est d'autres plastiques, cela n'a pas d'importance, laissez-moi un message et le responsable commercial vous proposera une solution parfaite en fonction de vos matières premières.

Shuliy est un fabricant de machines de recyclage de plastique digne de confiance, bienvenue pour visiter l'usine.

Matériaux applicables

Commun : bouteille de boisson froide telle qu'une bouteille d'eau minérale, une bouteille d'eau gazeuse, une bouteille de coca, etc.

Pour les autres plastiques, veuillez laisser un message et contactez-nous pour proposer des solutions exclusives.

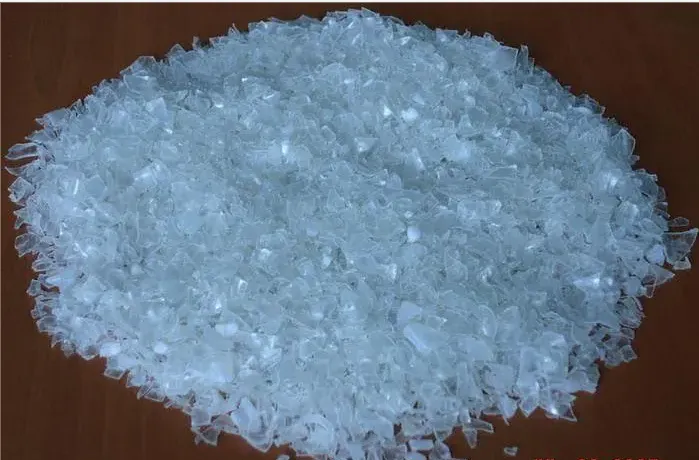

Flocons de plastique

Quelles machines sont incluses dans la ligne de lavage PET 1T ?

(Voici les principales machines fonctionnelles, moteurs, moteurs auxiliaires et autres accessoires non illustrés.)

Convoyeur

Tension : 380 V, 50 HZ, électricité triphasée

Puissance : 3KW

Longueur : 4000 mm

Largeur : 600 mm

Utilisé pour introduire les matières premières déstandardisées dans le concasseur

En option : bâton magnétique super puissant +6000

Machine de retrait d'étiquettes de bouteilles

Tension : 380 V, 50 HZ, électricité triphasée

Puissance : 15+3+1,5 kW

Longueur du canon : 4,3 m, diamètre 0,63 m

Épaisseur de la paroi extérieure : 8 mm

Flacon rond tarif hors norme 98%

Teneur en PVC/(mg/kg)≤100-300(mg/kg)

Tableau de sélection 6 m

Tension : 380 V, 50 Hz, électricité triphasée.

Puissance : 3kw.

6m de longueur.

Triez diverses bouteilles de matières premières colorées et contrôlez la teneur en couleur d'origine à ≥99,95%.

Teneur en PVC/(mg/kg)≤100-300(mg/kg).

Convoyeur2

Tension : 380 V, 50 Hz, électricité triphasée.

Puissance : 3KW.

Longueur : 6000 mm.

Largeur : 600 mm.

Utilisé pour introduire les matières premières déstandardisées dans le concasseur.

En option : bâton magnétique super puissant +6000.

Concasseur spécial PET

(Tapez 80)

Tension : 380 V, 50 Hz, électricité triphasée.

Puissance : 37+1,5KW+1,5kw.

Couteau : 9Crsi.

Transporter les matières premières du polyester vers le concasseur pour le concassage.

Sortie : 1000 KG/H.

Taille de l'écran : 18 mm.

Épaisseur de la lame : 40 mm.

Épaisseur du carton : 20 mm.

Assistance par levier hydraulique.

Outil optionnel : sk11+9000.

Convoyeur à vis

Tension : 380 V, 50 Hz, électricité triphasée.

Puissance : 4KW.

Longueur : 2500 mm.

Diamètre : 350 mm.

Machine de blanchiment et de distribution de filets

Tension: 380V, 50HZ, électricité triphasée

Puissance: 3KW

Séparer les impuretés des impuretés

Épaisseur de la paroi extérieure: 4mm

Épaisseur de la lame: 6mm

Dimensions de l'équipement: 5000*1000*1000mm

Teneur en polyoléfine de contrôle ≤200-300 (mg/kg)

Machine à laver à friction puissante

Tension : 380 V, 50 HZ, alimentation triphasée

Puissance : 7,5 KW

Longueur du canon : 3000 mm Diamètre : 400 mm

Utilisé pour le nettoyage par friction, l'élimination des impuretés et la filtration des sédiments

Épaisseur de la paroi extérieure : 4 mm

Épaisseur de la lame : 6 mm

Faire tremper la cuve de lavage chaude

Tension : 380 V, 50 HZ, électricité triphasée

Moteur 4kw

Puissance de chauffage électromagnétique : 80KW

Hauteur : 2000 mm Diamètre : 1300 mm

Épaisseur de la paroi extérieure : 4 mm

Épaisseur du fond du pot : 8 mm

Avec armoire de commande électromagnétique séparée

Utilisé pour tremper dans l'eau chaude, ajouter une solution alcaline, remuer et frotter, température de l'eau 85-95 ℃ pour éliminer les taches d'huile.

Machine d'alimentation en spirale (y compris la conversion de fréquence)

Tension : 380 V, 50 HZ, électricité triphasée

Puissance : 4KW

Longueur du canon : 5000 mm Diamètre : 320 mm

Épaisseur de la paroi extérieure : 4 mm

Épaisseur de la lame : 6 mm

Utilisé pour sortir les matières premières du pot de lavage chaud. La conception structurelle unique réduit les sorties d’eau chaude.

Rinçage du réservoir de lavage

Tension: 380V, 50HZ, électricité triphasée

Puissance: 3KW

Séparer les impuretés des impuretés

Épaisseur de la paroi extérieure: 4mm

Épaisseur de la lame: 6mm

Dimensions de l'équipement: 5000*1000*1000mm

Contrôle pH/pH≤8,0

Sécheur horizontal à grille complète

(avec cyclone)

Tension : 380 V, 50 HZ, électricité triphasée

Puissance : 15KW

Retirez l'eau, la sécheresse d'essorage est d'environ 95-98%

Épaisseur de la paroi extérieure : 4 mm

Épaisseur de la lame : 10 mm

Tuyau de séchage

Tension : 380 V, 50 HZ, électricité triphasée

Diamètre 159 mm, longueur 15 m

Puissance de chauffage 30kw, teneur en humidité de chauffage 0,5%

Moteur 7,5+3kw

Pièce de matériau de contact en acier inoxydable 304

Humidité (%) ≤0,5-1%

Séparateur d'air et machine de levage de matériaux

Tension: 380V, 50HZ, électricité triphasée

Diamètre 0,8m, hauteur 4,5m;

Moteur 2,2kw*3 Ventilateur auxiliaire: 0,75*3

Moteur de levage 3kw

Utilisé pour éliminer les marques fines résiduelles et la poussière

Épaisseur de la paroi extérieure: 3mm

Épaisseur de la lame: 6mm

Teneur en impuretés/(mg/kg)≤300-500

Teneur en poudre/(mg/kg)≤2000-3000

Machine d'affûtage automatique des couteaux

Tension : 380 V, 50 HZ, électricité triphasée

Moteur : 3+2,2 kw

Utilisé pour l'affûtage des couteaux, la marche automatique, le rinçage automatique

Armoire de distribution et accessoires divers