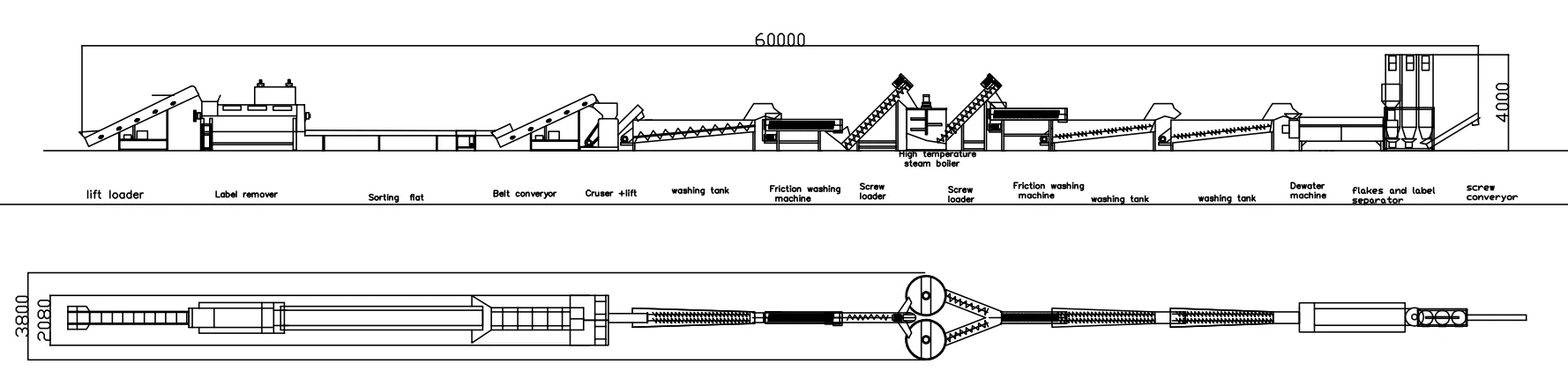

Línea de lavado y granulación de PET 1T

Proporcionar soluciones personalizadas

Línea de lavado y granulación de botellas de PET Shuliy

Nuestras líneas estándar de lavado y granulación de botellas de PET son soluciones completas para convertir botellas de PET sucias en hojuelas de PET limpias para procesarlas en gránulos de plástico o producir una variedad de productos plásticos terminados.

Ofrecemos capacidades de lavado granulado estándar desde 500 kg/hora hasta 5 toneladas/hora, y también podemos personalizar líneas de lavado de reciclaje de PET de mayor capacidad.

La línea de producción de reciclaje de PET de Shuliy es completamente automática y cada máquina de reciclaje está conectada mediante una cinta transportadora o un tornillo sin fin. Además, toda la línea de limpieza se puede controlar desde un panel y gabinete de control eléctrico central.

Si su materia prima son otros plásticos, no importa, déjeme un mensaje y el gerente de ventas le brindará una solución perfecta en función de sus materias primas.

Shuliy es un fabricante confiable de maquinaria para reciclaje de plástico, bienvenido a visitar la fábrica.

Materiales aplicables

Común: botella de bebida fría como botella de agua mineral, botella de agua con gas, botella de coca cola, etc.

Para otros plásticos, por favor deje un mensaje y contáctenos para brindarle soluciones exclusivas.

Escamas de plástico

¿Qué máquinas están incluidas en la línea de lavado de PET 1T?

(Las siguientes son las principales máquinas funcionales, motores, motores auxiliares y otros accesorios que no se muestran).

Transportador

Voltaje: 380V, 50HZ, electricidad trifásica

Potencia: 3KW

Longitud: 4000 mm

Ancho: 600 mm

Se utiliza para alimentar las materias primas no estandarizadas a la trituradora.

Opcional: Palo magnético súper fuerte +6000

Máquina de eliminación de etiquetas de botellas

Voltaje: 380V, 50HZ, electricidad trifásica

Potencia: 15+3+1.5kw

Longitud del cañón: 4,3 m, diámetro 0,63 m

Grosor de la pared exterior: 8 mm

Botella redonda tarifa fuera de estándar 98%

Contenido de PVC/(mg/kg)≤100-300(mg/kg)

Mesa de selección de 6m

Voltaje: 380V, 50HZ, electricidad trifásica.

Potencia: 3kW.

6m de largo.

Clasifique botellas de materia prima de varios colores y controle el contenido de color original hasta ≥99.95%.

Contenido de PVC/(mg/kg)≤100-300(mg/kg).

transportador2

Voltaje: 380V, 50HZ, electricidad trifásica.

Potencia: 3KW.

Longitud: 6000 mm.

Ancho: 600 mm.

Se utiliza para alimentar las materias primas no estandarizadas a la trituradora.

Opcional: Palo magnético súper fuerte +6000.

Trituradora especial PET

(Tipo 80)

Voltaje: 380V, 50HZ, electricidad trifásica.

Potencia: 37+1,5 KW+1,5 kw.

Cuchillo: 9Crsi.

Transporte las materias primas de poliéster a la trituradora para su trituración.

Salida: 1000 KG/H.

Tamaño de pantalla: 18 mm.

Grosor de la hoja: 40 mm.

Grosor del tablero de la caja: 20 mm.

Asistencia de palanca hidráulica.

Herramienta opcional: sk11+9000.

Transportador de tornillo

Voltaje: 380V, 50HZ, electricidad trifásica.

Potencia: 4KW.

Longitud: 2500 mm.

Diámetro: 350 mm.

Máquina blanqueadora y distribuidora de redes.

Voltaje: 380V, 50HZ, electricidad trifásica

Poder: 3KW

Separar impurezas de impurezas

Grosor de la pared exterior: 4mm

Grosor de la cuchilla: 6mm

Tamaño del equipo: 5000*1000*1000mm

Controlar el contenido de poliolefina ≤200-300 (mg/kg)

Potente lavadora de fricción

Voltaje: 380V, 50HZ, alimentación trifásica

Potencia: 7,5 KW

Longitud del cañón: 3000 mm Diámetro: 400 mm

Se utiliza para limpieza por fricción, eliminación de impurezas y filtrado de sedimentos.

Grosor de la pared exterior: 4 mm

Grosor de la hoja: 6 mm

Remojar la olla caliente

Voltaje: 380V, 50HZ, electricidad trifásica

motor 4 kw

Potencia de calentamiento electromagnético: 80KW

Altura: 2000 mm Diámetro: 1300 mm

Grosor de la pared exterior: 4 mm

Grosor del fondo de la olla: 8 mm.

Con armario de control electromagnético independiente

Se utiliza para remojar en agua caliente, agregar solución alcalina, agitar y frotar, temperatura del agua de 85 a 95 ℃ para eliminar manchas de aceite.

Máquina de alimentación en espiral (incluida la conversión de frecuencia)

Voltaje: 380V, 50HZ, electricidad trifásica

Potencia: 4KW

Longitud del cañón: 5000 mm Diámetro: 320 mm

Grosor de la pared exterior: 4 mm

Grosor de la hoja: 6 mm

Se utiliza para sacar las materias primas de la olla de lavado caliente. El diseño estructural único reduce la salida de agua caliente.

Enjuague del tanque de lavado

Voltaje: 380V, 50HZ, electricidad trifásica

Poder: 3KW

Separar impurezas de impurezas

Grosor de la pared exterior: 4mm

Grosor de la cuchilla: 6mm

Tamaño del equipo: 500010001000mm

Controlar pH/pH≤8,0

Secadora horizontal de rejilla completa

(con ciclón)

Voltaje: 380V, 50HZ, electricidad trifásica

Potencia: 15 KW

Retire el agua, el secado del centrifugado es de aproximadamente 95-98%

Grosor de la pared exterior: 4 mm

Grosor de la hoja: 10 mm

Tubo de secado

Voltaje: 380V, 50HZ, electricidad trifásica

Diámetro 159 mm, longitud 15 m

Potencia de calefacción 30kw, contenido de humedad de calefacción 0.5%

Motor 7,5+3kW

Material de contacto pieza hecha de acero inoxidable 304.

Humedad (%) ≤0,5-1%

Separador de aire y máquina elevadora de materiales

Voltaje: 380V, 50HZ, electricidad trifásica

Diámetro 0.8m, altura 4.5m;

Motor 2.2kw3 Ventilador auxiliar: 0.753

Motor de elevación 3kw

Utilizado para eliminar marcas finas residuales y polvo

Grosor de la pared exterior: 3mm

Grosor de la cuchilla: 6mm

Contenido de impurezas/(mg/kg)≤300-500

Contenido de polvo/(mg/kg)≤2000-3000

Máquina automática para afilar cuchillos

Voltaje: 380V, 50HZ, electricidad trifásica

Motor: 3+2.2kw

Se utiliza para afilar cuchillos, caminar automáticamente, lavar con agua automáticamente.

Gabinete de distribución y varios accesorios.